The research activities in the Turbomachinery field are:

Design, simulation and experimental analysis of turbomachinery components

- Development of 1D and 2D design tools for turbines, axial and radial fans and compressors, and for side channel blowers;

- Design and optimization of micro- and mini-gas turbines;

- Study of sustainable propulsion systems for naval applications, LNG-fueled COGES systems for cruise ships and ferries;

- Design of hydraulic turbines;

- Development and application of RANS and URANS computational fluid dynamic codes for the analysis and 3D design phase of turbines, axial and radial fans and compressors, and side channel blowers;

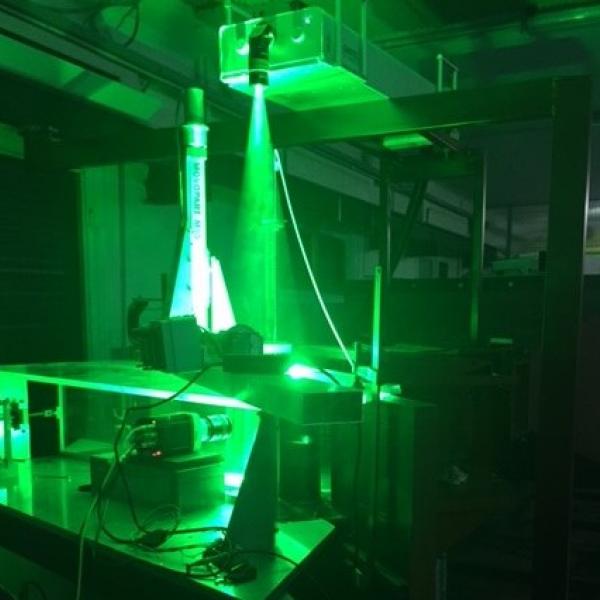

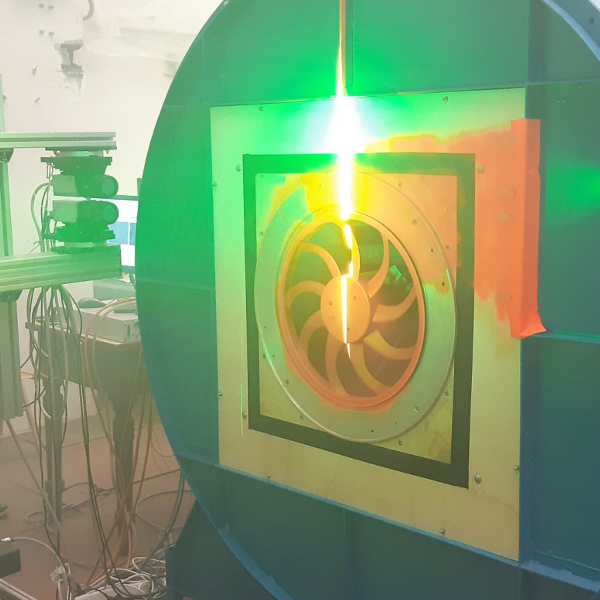

- Development of experimental techniques and advanced post-processing tools for the detailed analysis of the unsteady tri-dimensional flow field inside turbomachinery components;

- Development of Reynolds tensor closure models for RANS calculations using high-fidelity experimental and numerical databases;

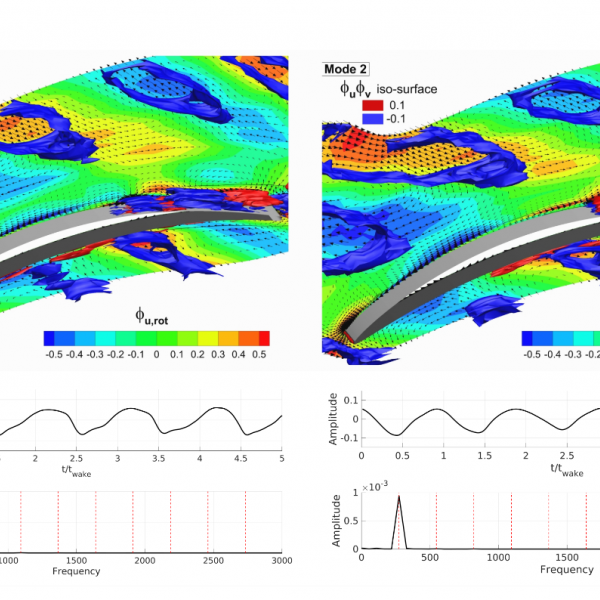

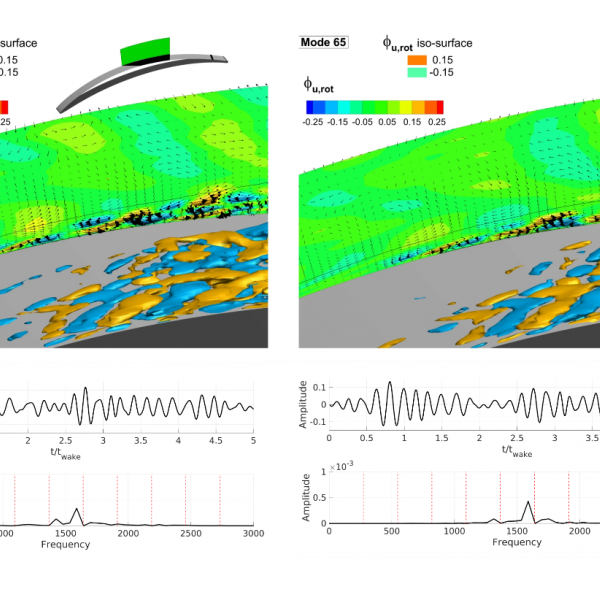

- Hi-fidelity simulations for the detailed inspection of the unsteady flow field of compressor and turbine blade cascades;

- Analysis of the aerodynamic noise generating mechanisms in fans and side channel blowers;

- Aeroelastic vibration (flutter) in axial fans;

- Development of big data analysis and machine learning tools for the calibration of models of complex system and identification and prediction, like turbomachinery and efficiency surface response linked to them.

Aeronautical propulsion and aeroengines

- Investigation of the rotor-stator aerodynamic interaction process in axial and radial turbomachines;

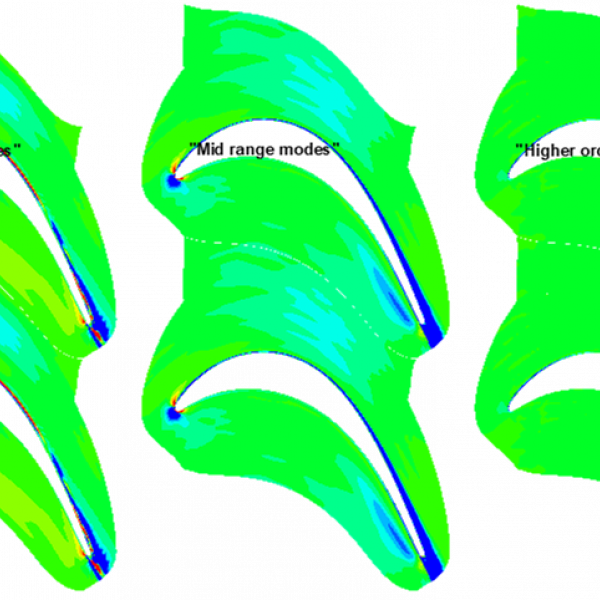

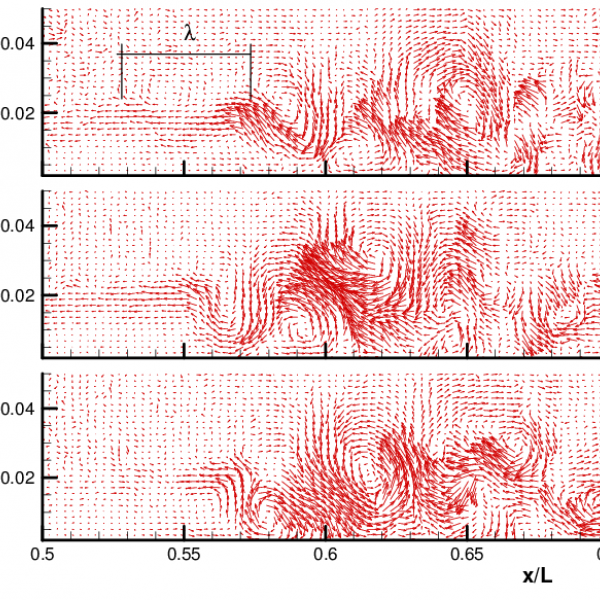

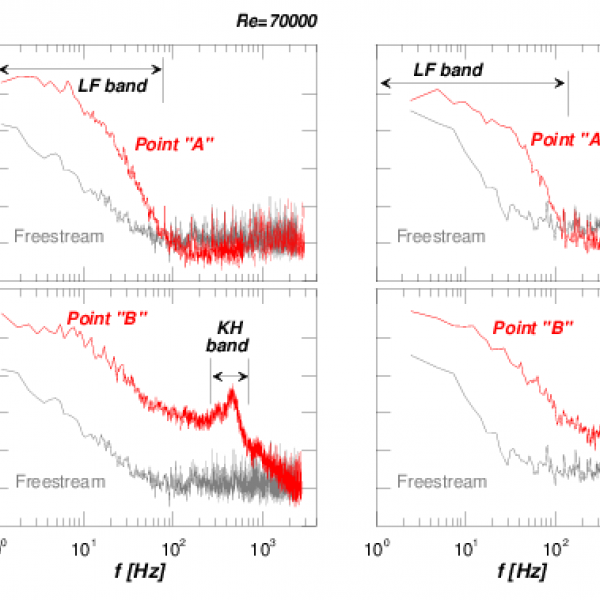

- Analysis of the transition and separation processes of the boundary layer for different flow and geometric parameters influencing the real operation of aeroengine components;

- Boundary layer transition and separation control with passive and active devices;

- Design of high lift and ultra-high-lift turbine profiles optimizing the loading distribution in the unsteady operation;

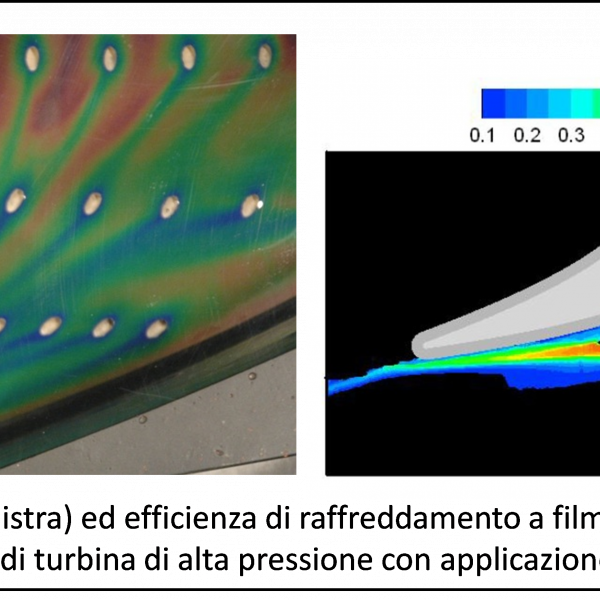

- Aero-thermal analysis of the cooling system for thermal insulation of high pressure turbine stages;

- Experimental and numerical investigation of the secondary and cavity flows in aeroengine turbine stages.

Laboratories

- Laboratorio di Aerodinamica e Turbomacchine - Flussi Interni dei Motori Aeronautici –Genova

- Laboratorio di Aerodinamica e Turbomacchine - Flussi Interni dei Motori Aeronautici –Savona

- Laboratorio di Combustione – Aeroacustica – Fluidodinamica Numerica - Genova

- Laboratorio di Combustione – Aeroacustica – Fluidodinamica Numerica - Savona

Representative Publications

- Dellacasagrande, M., Barsi, D., Lengani, D., Simoni, D., Instability processes in short and long laminar separation bubbles Experiments in Fluids, 2024, 65(7), 109

- Dotto, A., Satta, F., Campora, U., 2023, "Energy, environmental and economic investigations of cruise ships powered by alternative fuels", Energy Conversion and Management, Volume 2851

- C. Cravero, D. Marsano, V. Sishtla, C. Halbe, W.T. Cousins, Numerical Investigations of Near Surge Operating Conditions in a Two Stage Radial Compressor with Refrigerant Gas, ASME Journal of Gas Turbine and Power, DOI: 10.1115/1.4063577, vol 146, pp 021010-1-13, Feb. 2024

- Dellacasagrande, M., Canepa, M., Cattanei, A., Moradi, M., Characterization of Unsteady Leakage Flow in an Axial Fan International Journal of Turbomachinery, Propulsion and Power, 8(3), 34, 2023

- Canepa, E., Cattanei, A., Moradi, M., Nilberto, A., Experimental Study of the Leakage Flow in an Axial-Flow Fan at Variable Loading M., International Journal of Turbomachinery, Propulsion and Power, 6(4), 40, 2021