The Laboratory was founded in the 1980s based on previous experiences developed at the University of Genoa's Institute of Machinery and conducts extensive research on the aerodynamics of turbomachinery for energy conversion and aircraft propulsion. It has been and continues to be involved in numerous research projects funded by the European Community and the Ministry of Education, University and Research (MIUR) aimed at developing technologies to improve the aerodynamic performance of turbomachinery components. It is a reference laboratory for GE AvioAero, conducting applied research on the development of next-generation engine components aimed at reducing environmental impact and specific fuel consumption.

The Laboratory is equipped with the following experimental facilities:

- Wind tunnel for studying the control of boundary layer separation and transition on industrial component surfaces (diffusers, air intakes, blade surfaces, etc.) using active (suction, blowing, or zero-net-flow pulsed jets) and passive (turbulators and vortex generators) control techniques.

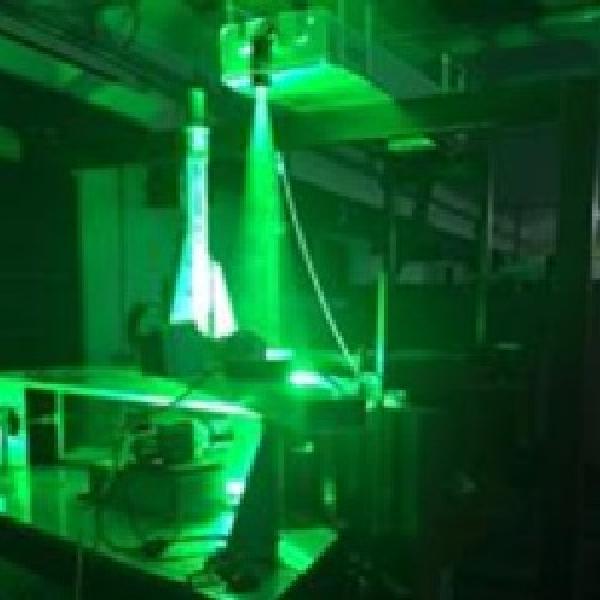

- Open-circuit wind tunnel for large-scale blade arrays, equipped with a rotating bar system to study blade wake-boundary layer interaction.

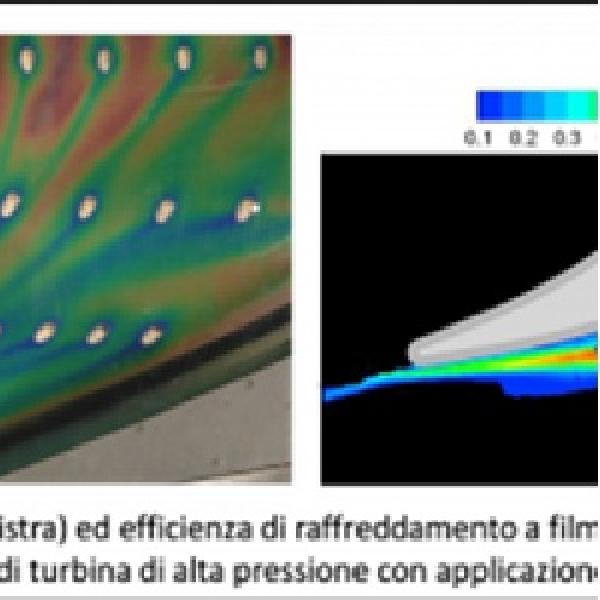

- Open-circuit wind tunnel for large-scale blade arrays, equipped with a high-temperature secondary air system to study blade and endwall cooling in gas turbines.

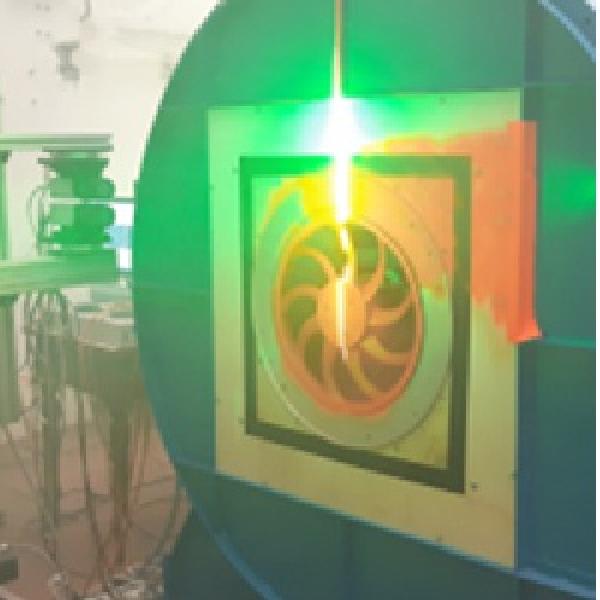

- Single-stage turbine model for detailed flow studies in highly loaded rotors of aircraft turbines.

- Two-stage turbine model with seals for cavity flow and secondary air system (SAS) testing.

Location

- Laboratory of Aerodynamics and Turbomachinery - Aero-Engine Internal Flows Genova

Researchers

- Marina Ubaldi

- Daniele Simoni

- Davide Lengani

- Francesca Satta

- Giovanni Tanda

- Dario Barsi

- Matteo Dellacasagrande

- Daniele Petronio

Research Topics

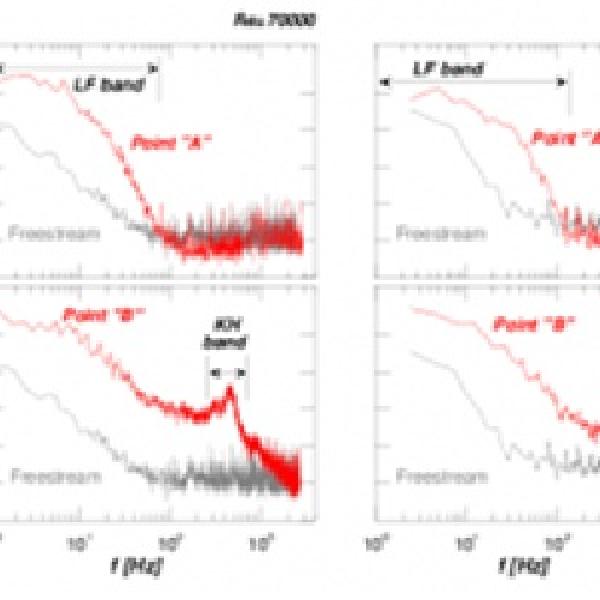

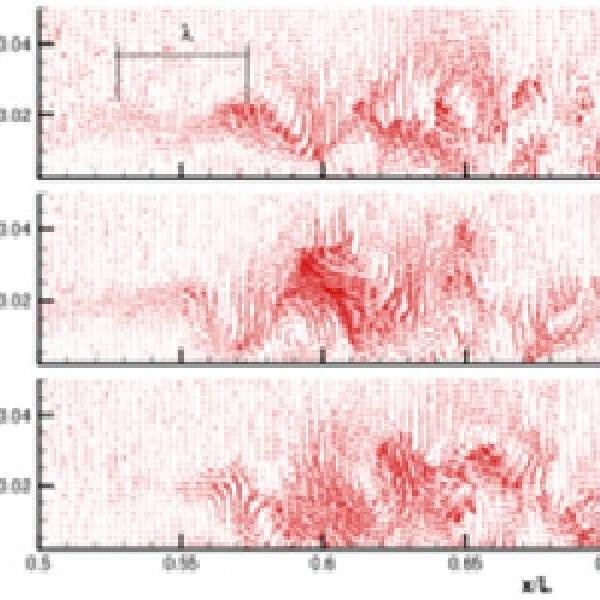

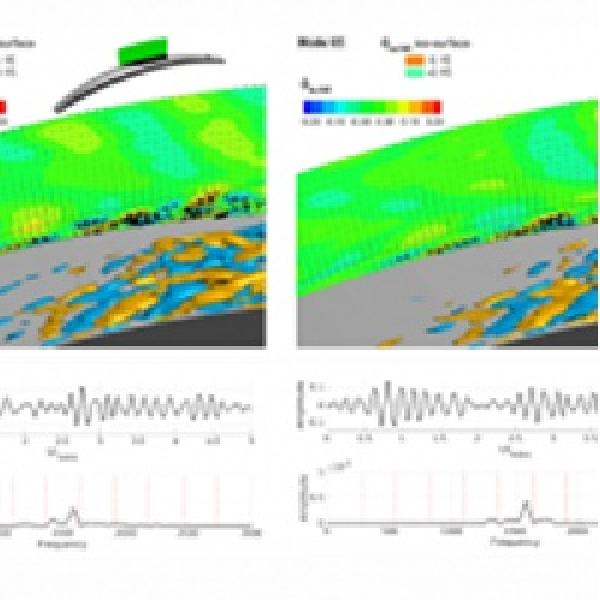

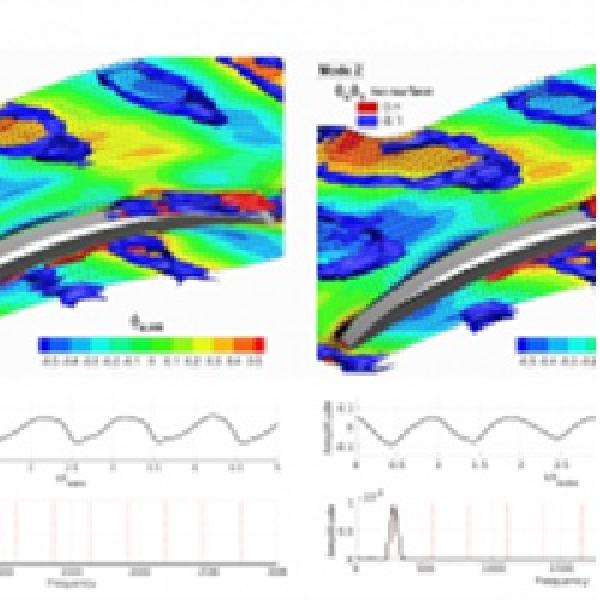

- Development of experimental techniques for the analysis of unsteady and turbulent flows;

- Development of big data analysis and machine learning tools;

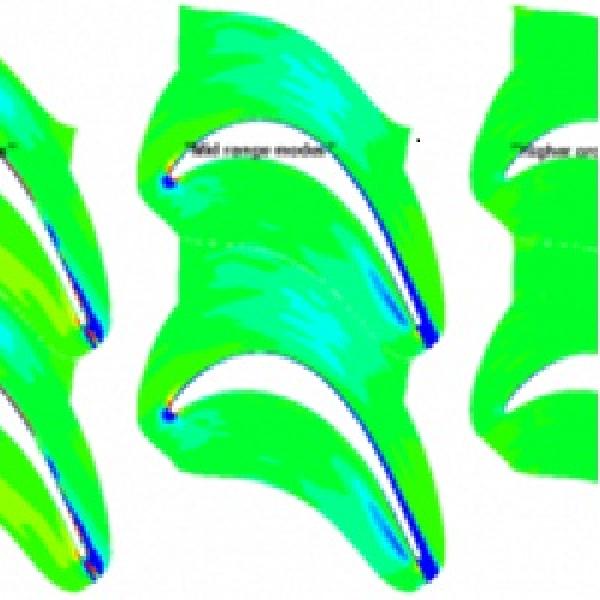

- Boundary layer and profile wake transition and separation control;

- Analysis of the unsteady rotor-stator interaction process in low pressure turbine modules;

- Development and design of highly loaded low pressure turbine profiles for aeroengine applications;

- Development of new techniques for thermal effectiveness measurements of cooling system for blades and endwalls;