The laboratory includes various equipment, in particular:

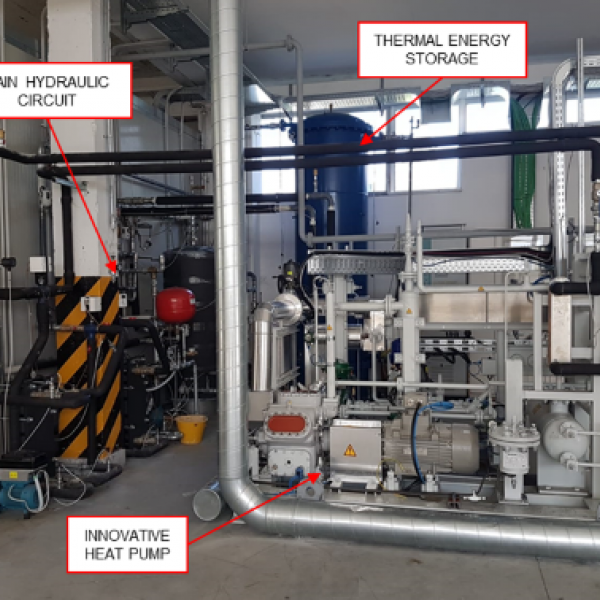

- Experimental plant (European H2020 PUMP-HEAT project), consisting of a TURBEC T100 turbine coupled to a real-time steam cycle model, resulting in a cyber-physical combined cycle, coupled in turn with an innovative heat pump and thermal storage via an intermediate hydraulic circuit. The aim is to evaluate system performance, focusing in particular on the flexibility of combined cycles.

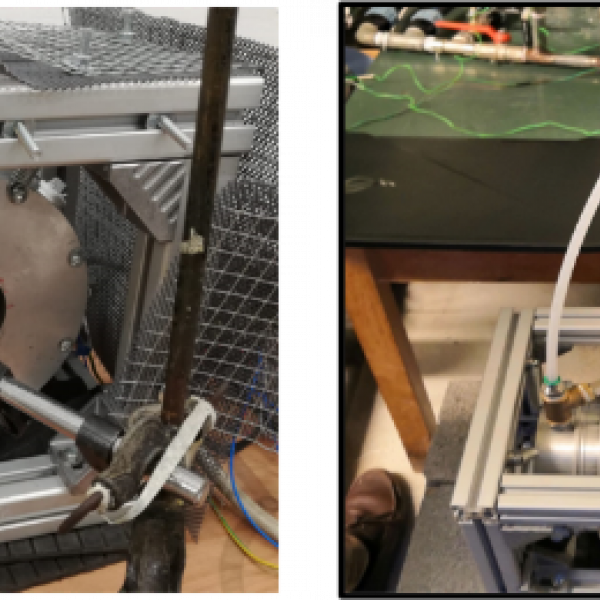

- Test rig for the performance evaluation of innovative Tesla-type turboexpanders: the test rig consists of a set of sensors and flow controllers that manage the air supply to the non-bladed Tesla turbine. The machine's electric motor/generator is controlled by a dedicated electronic driver. Alternatively, if the Tesla operates with incompressible fluids, it can be supplied with water in another sensorized, open-cycle test rig where water from the mains is pumped to the desired turbine inlet pressure.

- A test rig for the operation and performance evaluation of innovative reverse-cycle machines – the result of a collaboration between Carrier Corporation and the University of Genoa. This is a chiller where fluid compression is handled by a completely oil-free dynamic compressor. The objective of this rig is to evaluate the performance of the chiller and dynamic compressor under design and off-design conditions, with particular attention to studying any instability that could arise in the compressor. The chiller can be equipped with various types of condenser-side heat exchangers and has an injection system that allows for the study of the compressor's behavior when receiving a mixture of liquid and gas refrigerant droplets at the intake.

- This test rig is dedicated to the emulation of PEM fuel cells: it is composed of a Tesla-type compressor that feeds air to a saturator that simulates the chemical reactions in the fuel cell by saturating the air with water (heated by resistors), an internal exchanger, and finally a Tesla turbine for recovering part of the energy at the exhaust.

- A test rig dedicated to similarity testing of ejectors for recirculation within PEM fuel cells: the rig is equipped with a dried air line for feeding the primary flow to the ejector nozzle and a recirculation system for the secondary flow; the recirculation system can be heated by special resistors.

- The laboratory houses research equipment and prototypes previously developed by Rolls-Royce Fuel Cell Systems as part of the research program for a 1MWe pressurized SOFC fuel cell unit. This equipment is currently being used for educational and illustrative purposes.

- In the near future, a thermal storage system using a supercritical carbon dioxide heat pump will be set up. The system will also have a discharge cycle to use the stored thermal energy as a source for electricity generation. Considering both cycles together, the system will constitute a "Carnot battery."

Location

- Centrale di Tirreno Power, via Armando Diaz, 128, 17047 Valleggia (SV)

Reaserchers

- Prof. Alberto Traverso (RADRL)

- Dr. Matteo Pascenti (Building Manager)

- Dr. Federico Reggio (Operations Manager)

- Prof. Mario L. Ferrari

- Dr. Silvia Crosa

- Prof. Loredana Magistri

Research Teams

- Combined Cycle Power Plants

- Microturbines (traditional machines)

- Microturbines (Tesla machines)

- High temperature components for advanced systems

- SOFC fuel cells

- Advanced heat pumps

- Energy recovery

- Control systems

- Energy storage systems