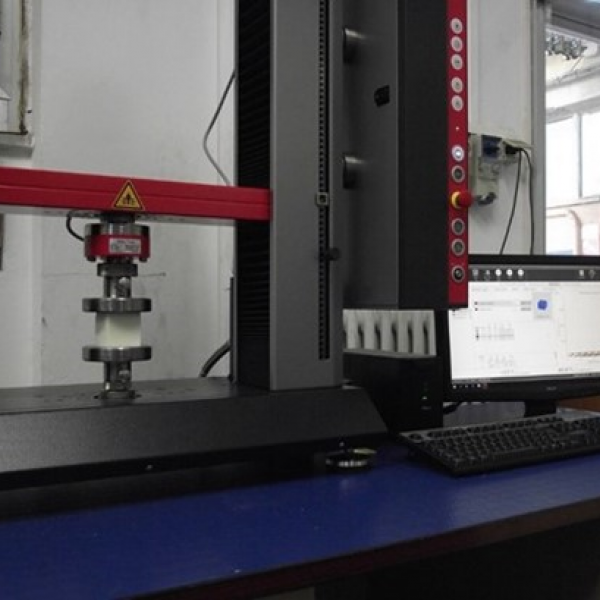

The mechanical characterization laboratory is dedicated to conducting tests on materials and components, as well as developing innovative experimental methodologies as needed.

The experimental results, obtained through standardized tests or under complex loading conditions, are used for the development and calibration of mathematical and numerical models of the mechanical behavior of materials in order to perform behavior simulations as faithfully as possible to real responses. For this purpose, various simulation software (Ansys, Altair Hyperworks, Abaqus, Hyperfit, LAMMPS, etc.) and identification and optimization techniques and software (Altair Hyperworks, Altair Optistruct, Lunar Odyssee) are used.

The main experimental equipment includes:

- Electromechanical universal testing machine Zwick Z010 (capacity 10 kN)

- Hydraulic universal testing machine Schenck Hydropuls 250 (capacity 250 kN)

- Schenck pulsator (capacity 80 and 180 N m)

- Hydraulic universal testing machine Giuliani 100 (capacity 100 kN)

- Schenck rotating bending machine

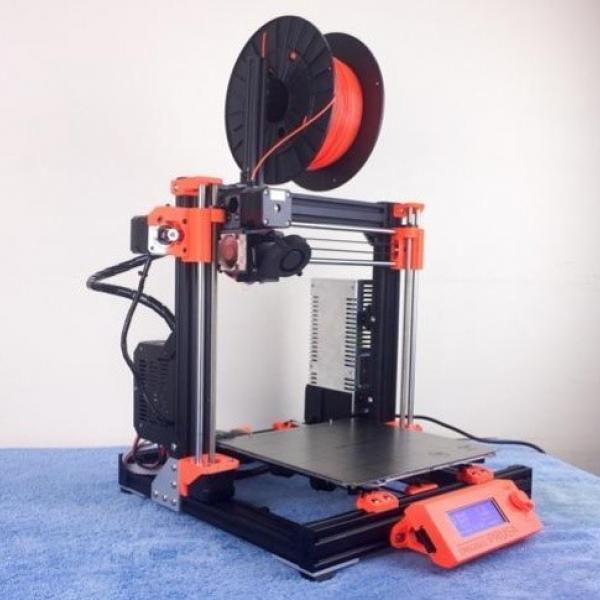

- 3D printer with FFF technology (Prusa i3 MK2s and MK3)

Locations

- L1, Via All’Opera Pia 15/A

- Laboratorio di Misure, Materiali e Biomeccanica, Via Giuseppe Fasce 1

Researchers

- Massimiliano Avalle

- Flavia Libonati

- Margherita Monti

Research Topics

- Characterization of plastic materials, including those processed with additive manufacturing technologies

- Characterization of composite materials

- Characterization of cellular materials and lattice structures

- Characterization of bio-inspired materials

- Creation of new structures or materials in Additive Manufacturing

- Characterization of bonded joints